Written by Dr. Julian Conejo

With the advances on intraoral scanning, CAD/CAM (Computer Aided Design/ Computer Aided Manufacturing) technologies and digital implantology, the need for a predictable and user-friendly

3D printing system has become a necessity for clinicians and dental technicians for completion of a true digital workflow.

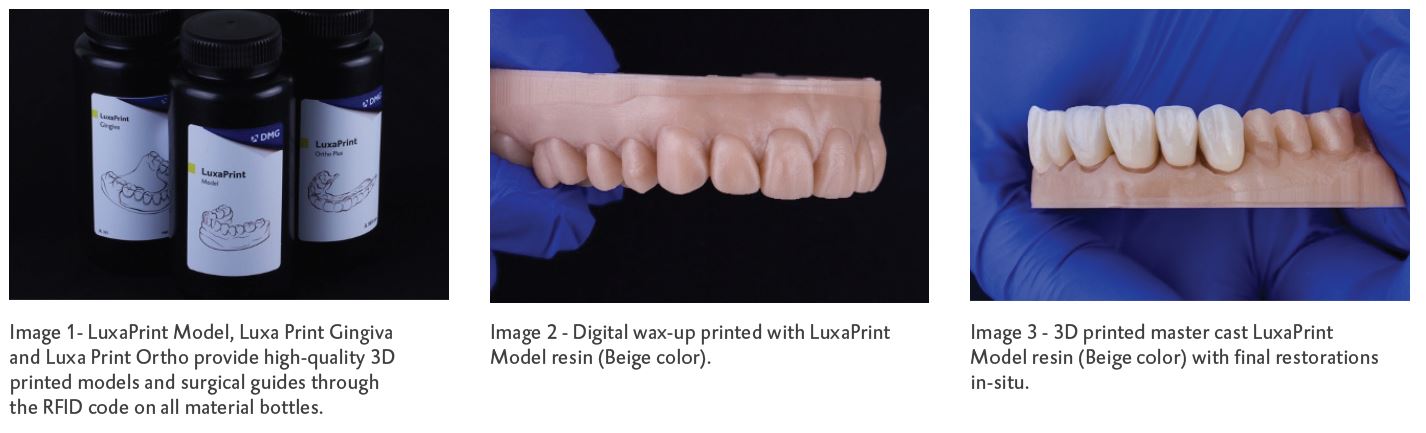

DMG’s newly released integrated 3D printing solution offers this user-friendly and simplified solution, for a seamless integration of the digital workflow. The DMG digital system includes a

validated software-supported, reproduction technology process accepting all standard .STL files. The 3Demax digital printer, 3Dewash and 3Decure units communicate via internet. By scanning the RFID code on all LuxaPrint material bottles, optimal process reliability can be obtained. (Image 1)

The LuxaPrint family of materials for 3D printing provides confidence in choosing high-quality resins for precision and accuracy of 3D printed dental devices with a wide range of applications.

All LuxaPrint materials may be used with the following printers: DMG 3Demax, Straumann P20+ & P10+ capsule and Rapidshape D30, D20+, D20+ cartridge and D10+ units.

DMG LuxaPrint resins provide clinicians and dental technicians 6 different resins, with 3 additional resins coming late 2021.

LuxaPrint Model, for elaboration of high precision models. (Image 2-3)

LuxaPrint Gingiva, for optimal elastic and high tear resistant gingival masks.

LuxaPrint Cast, allowing easy fabrication of residue-free and easy-burn casting of copings and frameworks.

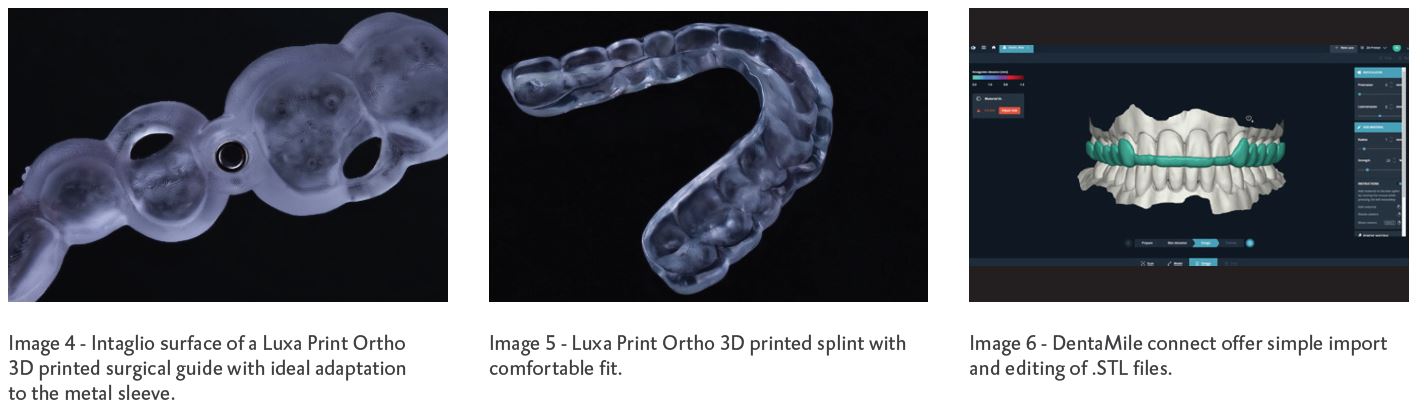

LuxaPrint Ortho and Luxa Print Ortho Plus (coming soon), covering the broad-spectrum of clinical needs for the production of surgical guides, night guard and splints with clear transparency

even after sterilization. (Image 4-5)

LuxaPrint Ortho Flex, a biocompatible material for flexible soft splints for bleaching, and indirect bonding trays.

LuxaPrint Tray, supporting prosthetic digital workflows need for custom trays.

LuxaPrint Crown (coming soon), for 3D printing of semi-permanent crowns and bridges.

LuxaPrint Base (coming soon), for long-term stability of denture bases.

DMG will continue to simplify their user-friendly platform with the introduction of an intuitive cloud-based design software late, 2021. DMG’s DentaMile connect software will facilitate the

integration of 3D printing workflows into dental clinics and laboratories for a shortened learning curve allowing rapid organization, design, communication and printing with predetermined

parameters for each material. (Image 6)

When all variables have been considered, a smooth integration of the LuxaPrint family of materials into a user-friendly, comprehensive software and robust hardware, predictable clinical and laboratory solutions are rapidly obtained. DMG’s new 3D printing materials offer an endless number of possibilities for clinical implementation and benefit of patients worldwide. As additive production of provisional and semi-permanent crowns and bridges grow, the need for a reliable 3D printing solution is extremely important and will provide a smooth transition for clinicians and dental technicians into modern dentistry.