DMG does it all: No tech savvy required

Jeffrey C. Hoos, DMD

Introduction

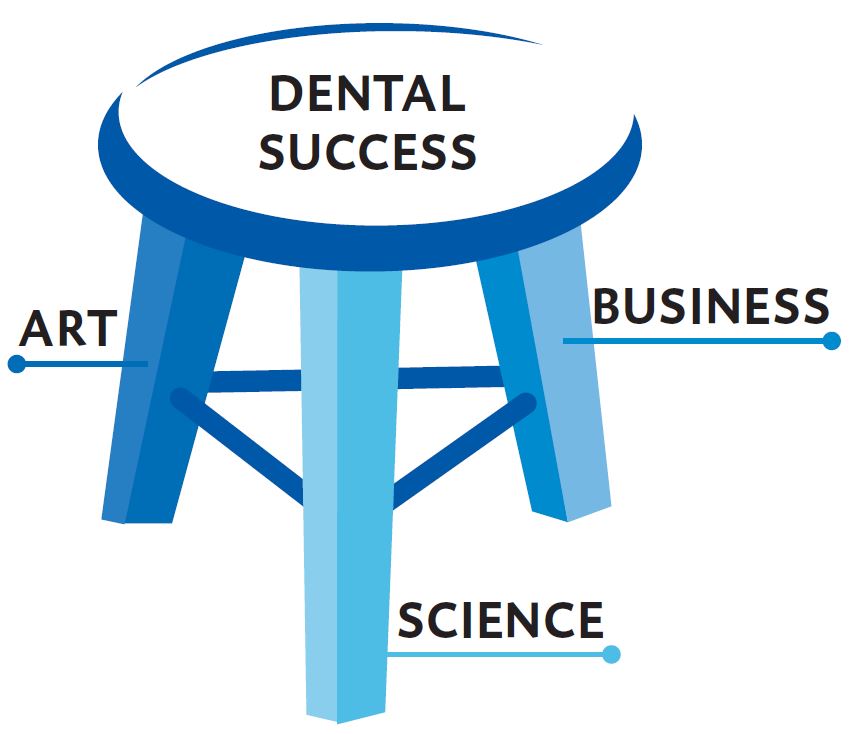

It only took me 40 years of private practice to figured out what I think is the key to building a successful dental practice: BALANCE. Specifically, I believe that dental success rests on the following “3-legged stool”:

- Art: Creating something that is beautiful

- Science: Using an evidence-based approach incorporating based on the latest research

- Business: Being able to reproduce procedures in a timely manner

I’ve learned that it’s not only possible to balance the art, science and business of dentistry, it’s essential. While working on my MBA, I came across a well-known venn diagram used in the business world to interface the concepts of Good, Fast, and Cheap. In effect, the businessperson says to her or his customer, you can choose only two of the three. If you want it fast and good, you will have to pay extra.

businessperson says to her or his customer, you can choose only two of the three. If you want it fast and good, you will have to pay extra.

If you want cheap and fast, it will not be good. And if you want good and cheap, you’ll be waiting for the product until whenever I can get to it.” We have all learned it is not possible to have all three at the same time if we want to earn acceptable return on our investments in our practices.

While we might not be able to be good, fast, and cheap, I believe it is possible to be good, fast and affordable – with “affordable” being defined as “delivering good value.” As businesspeople – and all dentists are businesspeople – it is crucial to understand that you don’t have to be cheap in order to offer good value. And this applies not only to the services we offer our patients, but to the products we purchase from dental manufacturers.

In order for a practice – especially a fee-for-service practice like mine – to deliver artful dentistry based on good science with affordable fees, we have to be able to do what we do in a timely enough manner to earn an acceptable return on our investment. The advent of CAD/CAM technology and “same day dentistry” made it possible both to appeal to patients who appreciate not having to return for another visit and to earn a great return on investment. Utilizing an intraoral scanner and 3D printing presents the same opportunity.

Why 3D printing?

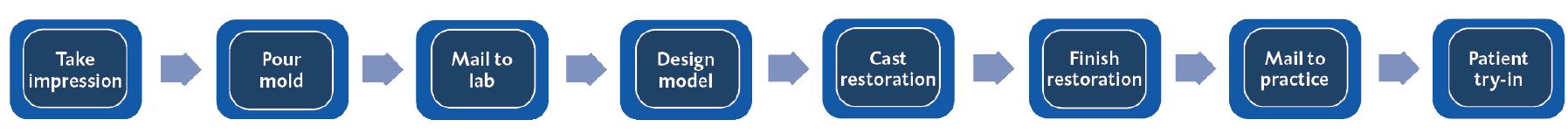

3D printing saves time for both practices and patients, largely because it greatly reduces the risk of error. Let’s look at the process of making a partial denture conventionally, which presents at least eight opportunities for error:

Each error costs time, and lost time means lost profits and – more importantly – reduced patient satisfaction.

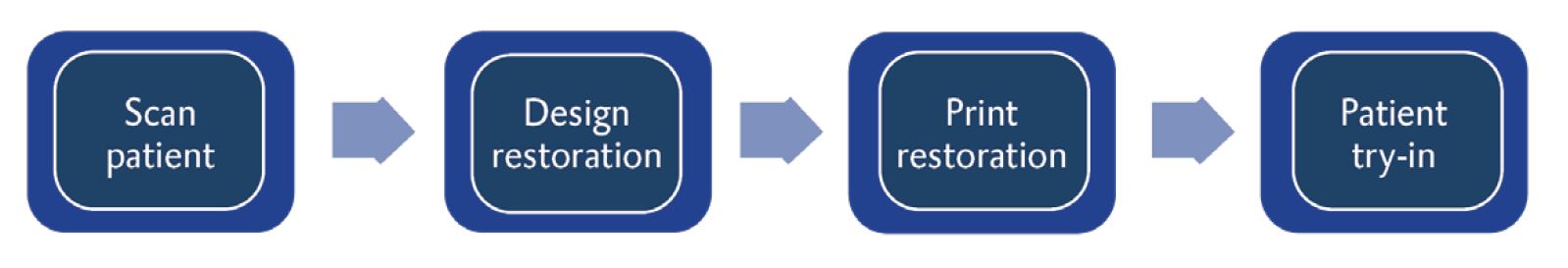

In contrast, 3D printing vastly reduces the possibility of human error by eliminating pouring of molds, manual designing models, and casting and finishing restorations:

This streamlined process also saves time by eliminating the needs for mailing molds to labs and restorations to practices, not to mention the risk of packages being lost or damaged in the mail.

In addition, halving the number of steps introduces the opportunity to enhance office productivity by combining treatments for the patient, such as cleaning their teeth while the restoration is being printed. Moreover, the scanning step in the 3D printing process is much more comfortable for the patient than alginate impressions.

There is a significant “wow factor” for the patient with 3D printing, just as there was when we replaced traditional “dip and dry” x-rays and their radiation exposure risk with digital x-rays. When’s the last time you had a discussion about whether digital x-rays made sense for your practice and patients? It is not even a question anymore; it’s a fait accompli. And I think the same will be true of 3D printing.

While 3D printing can’t yet be used for final restorations, I personally believe that day isn’t too far away. And when that day arrives, 3D printing of final restorations is going to be better, cheaper and faster than milling them from zirconia or other milling materials. For this reason, I’ve chosen not to add a milling unit to our practice even though I have certified lab technician on my staff.

Implementation

The first implementation step, of course, is setting up your 3D printing system. Wanting to get our system up and running as soon as possible – and being about as far from a “tech geek” as you can get – I opted to have the manufacturer install our system for us. It proved to be a wise decision.

The next step – staff training – is critical, and I urge you to select a manufacturer that excels at it. Trying to figure it out on your own will only delay your ability to experience the full benefit of this technology, and it could lead to errors that inconvenience and frustrate your patients.

Another important decision you will need to make is who will be responsible for executing the 3D printing process in your practice. I am a firm believer in delegating to my staff as much as I possibly can. My job is to be chairside, to interface with my patients. If I can delegate something that would otherwise interfere with that role, I will do it every time. So, my staff handles all of the scanning and all of the 3D printing, and they’ve been doing a terrific job. Having said that, change is always challenging, and it is important that the dentist be the enthusiastic cheerleader whenever you bring a new technology into your practice. Our 4-dentist, 25-staff practice has always designated one of our staff members to be the champion of any new technology – whether it be going paperless, adding 3D navigation for implant surgery, or now adding 3D printing – and I highly recommend this approach to you.

One part of new technology implementation that is too often overlooked is marketing its benefits to your patients. In the case of 3D printing, you’re really missing out on a chance to “wow” your patients if you don’t call attention to how much more comfortable scanning is versus conventional impressions, and how much time it’s saving them. The wow factor of 3D printing can generate the best possible kind of advertising: word of mouth. A lot of times I’ll give patients a copy of their 3D model to take home, which I’ve found to be a great way to get your patients talking.

R.O.I. (Return on Investment)

They didn’t teach us much about ROI in dental school, but making smart investment decisions is more critical than ever in running a successful practice. And an important part of ROI analysis is having the right fee structure.

Getting a 3D printer can definitely save you money. The question is, what do you do with those savings? Do you keep your prices the same and pocket the extra profit? Or do you pass the savings onto your patients? There is no question that many dentists will opt for the increased profit. In my opinion, however, that might actually not be the most profitable alternative. The reason is that it doesn’t take into account an often-overlooked intangible aspect of a return on investment calculation: patient perception. A patient’s perception of how you run your practice greatly affects the likelihood they will stay with you. And if lowering your price increases your patient’s loyalty and the number of new patients their word-of-mouth support draws to your practice, then that’s the option that will maximize your profitability.

To be fair, you could certainly argue that you would be justified in not passing the cost savings onto to your patients since they are already getting the benefit of not having to make as many trips to your practice. In my case, I’ve decided that if a breakthrough technology lets me reduce my overhead – especially if, like 3D printing, it also saves me time I can use to do more procedures – I owe it to my patients to reduce my fees accordingly.

Why I chose DMG?

I can tell you I did not pick DMG because they have the cheapest 3D printing solution. As you can tell from my earlier comments, taking the cheap route is never my preferred option. And that’s especially true in this case, as DMG has put together an integrated suite of products whose benefits easily justify a premium price for me.

I cannot stress enough how important it is to buy a good 3D printer. If you do not have good models, you’ve absolutely increased your error, and that’s not good art, good science or good business. DMG’s high-speed digital light processing (DLP) printer, the 3Demax, accepts all standard STL files. It can be used to produce surgical guides, burn-out casting molds, mouth guards, occlusal splints, crowns and bridges, physical models and more.

The 3Demax also incorporates radio-frequency identification (RFID) technology that makes it easy to automatically identify the material you’re about to use in order to eliminate the possibility of misapplication. This is a brilliant benefit that, to my knowledge, no one else offers.

The second component of DMG’s fully integrated suite of 3D printing hardware is the 3Dewash washer, which uses pre-set programs to systematically wash the remaining non-polymerized resin from the dental model. The third and final component is the 3Decure curing unit, which uses 360° illumination and pre-set curing programs that lock in the printed devices’ mechanical properties to make sure the curing is consistent with the individual resin’s specifications. All three pieces of hardware are very well made and very robust and have a very small footprint.

I use this 3D printing system primarily for temporary restorations, like custom trays or aligners. I also use it to print models for some of my larger cases – like those involving implants – when a scan isn’t feasible. For all of these applications, the accuracy produced by this integrated solution is every bit as good as it is with the conventional approach. Importantly, however, the durability is much better, and the process is much easier.

Having all three components manufactured by the same company definitely helps with my peace of mind, as does the fact that DMG also provides the LuxaPrint line of high-quality light-curing resins. Five different types are currently available, with four more slated for later in the year. I’ve been a fan of other DMG materials for years, and it’s clear that the LuxaPrint line is up to those same high standards.

I’m currently using Netfabb software, and so far, it’s been great. In a few months, DMG will be introducing its DentaMile connect software, which will integrate with its three pieces of hardware. It is a cloud-based design software that will secure and validate the fabrication workflow for the printed devices. As much as I love this 3D printing solution now, I can’t wait to see how much better it is with DentaMile connect.

While I could not be more pleased with DMG’s hardware and materials, I might be even more impressed with their customer support. They came to our office, trained our staff, installed the entire system and quickly got it up and running. Just as I want my patients to feel that I’m offering them great value, I want to feel the products and services I buy are giving me an outstanding return on investment. And that is what you get when you invest in the highest quality product, the best materials, and the best support.

Conclusion

Every dentist needs a mission statement. This is mine: “To provide the highest quality of care, for the greatest number of patients, while maintaining a balance between the art, science and business of dentistry.” If you can win the constant battle to achieve that balance – with the right mission statement, the right staff, and the right technology – success in private practice will be yours.

There is a simple question I ask myself to help determine if a new technology is likely to help me pursue that mission: Is this technology worth more to me than the money that is in my pocket? That is what I asked myself before deciding to add 3D printing as another powerful arrow in my quiver to fight the battle against dental disease.

For years I’ve felt that the best investments I’ve ever made in my practice were introducing cone beam technology and digital x-rays. Based on my experience to date, I’m pretty sure that bringing DMG’s 3D printing solution to my practice will rival them as my best investment ever.