3Demax

How do I design models to print?

Design software such as 3Shape or Exocad can be used to design a device. The STL file of the device can be exported for 3D printing. DMG will be soon offering a cloud-based design software, DentaMile connect.

Does the 3Demax printer need to be calibrated? How often?

Yes, the printer needs to be calibrated. Calibration ensures your printer is always working optimally. We recommend calibrating the printer once a week using the light sensor. A video guide can be found here: https://dmg-connect.com/3d-printing-getting-started-videos/

What is the accuracy of the 3Demax?

The 3Demax has a resolution of 34 microns in the x and y direction/axis and can support layer thickness of 30 microns.

What does DLP stand for?

DLP stands for Digital Light Processing

How does Digital Light Processing work?

When an object is ready to print, the build platform descends into the resin filled tank. A light projector underneath the tank projects a UV light and cures the first layer to the build platform. The UV light energy cures the resin to the build platform due to the chemical reaction. The build platform then slightly raises and comes back down to cure the next layer. This process is repeated until the entire object is printed. The printed device needs to be washed so the left-over resin doesn’t distort the object followed by a final cure so the mechanical properties are locked in. The supports should be removed after the final curing to avoid any distortions.

What are the technical specifications of the 3Demax?

- The 3Demax is compact – 335 x 541 x 349 mm

- It has a resolution of 34 microns

- It is comprised of:

- Building plate that is 130 x 75 x 90 mm

- LCD display that easy to follow instructions or information such as the print job time

- Light source at the base of the printer that outputs a 385 wavelength UV LED

- It provides connectivity via WLAN (wireless), TCP/IP (networked) and USB

Does Force Feedback impact accuracy and curing?

The force Feedback is a feature which accelerates the device function/device performance. The function has no impact on accuracy of the printing process.

What are the system requirements the Netfabb software?

The following are the system requirements:

- Operating System

- Microsoft Windows 10 (64 bit)

- Microsoft Windows 8.1 (64 bit)

- Microsoft Windows 7 SP1 (64 bit)

- NOTE: Windows 32-bit version or older, Linux, and Apple OS are not supported

- CPU Type

- Intel Core i5 (2.8+ GHz)

- Working Storage

- 8 GB RAM

- Graphic Card

- OpenGL 3.3 graphic card with 2 GB

- Screen Resolution

- Minimum 1280 x 1024 Pixel

What is the size of the build platform?

The 3Demax build platform size is 5.12 x 2.95 x 3.54 inches.

What is Force-Feedback?

The “Force-Feedback” is an option that accelerates the printing process. Using a highly sensitive load cell, the “Force Feedback” program controls the removal process of the printed piece after curing. It monitors and measures the force of each layer when being printed and adjust it during the printing process allowing it for a faster printing speed.

What impacts printing speed of the printer?

The layer thickness and device’s height will impact printing speeds

How does orientation of the product impact print times?

An object that is flat on the build platform takes less time to print since there are less layers to print. An object that is angled on the build platform takes longer to print since there are more layers to print; however, more objects can be added to the build platform.

What is the lifespan of the resin reservoir tank?

The resin reservoir can last for approximately 300 printing cycles.

How much material does the reservoir tank take?

The material reservoir can store up to 40% of the filling level.

What are supports?

Supports are structures that are added in the Netfabb slicing software that help the device being printed remain stable during the printing process. The supports can be automatically or manually added. The supports can be easily snapped off and finished after curing.

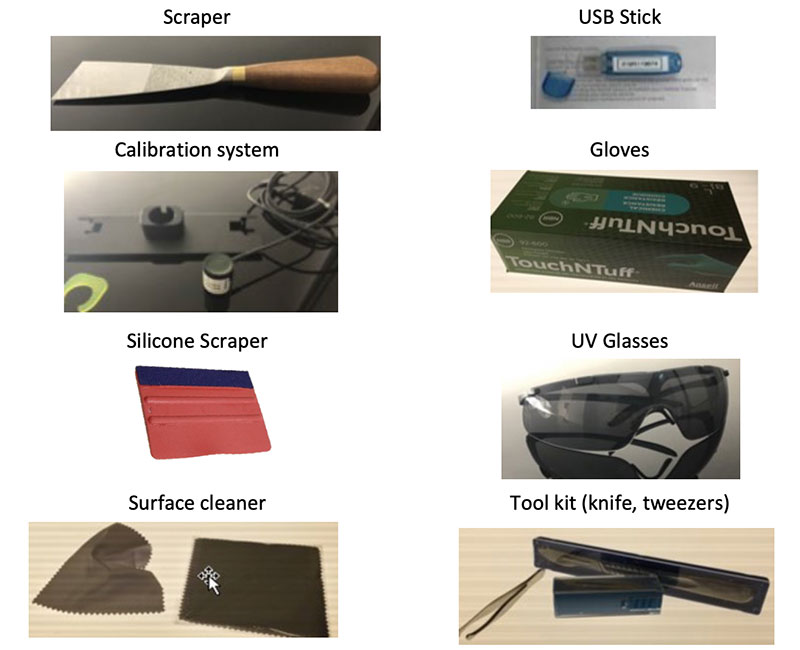

What accessories are available with the DMG 3D digital printing solution?

These are the standard accessories that are part of the DMG 3D Digital Solution.

How is the printer and the accessories cleaned?

The parts of the printer that can be cleaned such as the build platform can be done with alcohol to wipe any resin that might have dripped. The bottom of the reservoir tank can be cleaned with the silicone scraper and window cleaning solution such as Windex.

How does the RFID technology work?

Both the 3Demax printer and the LuxaPrint resins are equipped with RFID (Radio Frequency Identification) technology. The 3Demax printers has a RFID reader and each resin will have its own programmed RFID chip. The bottle of resin is placed by the printer RFID reader which reads the information from the bottle and writes it to the resin reservoir tank. It minimizes errors and ensures reliable automatic identification of material for each print job.

How do I identify the material to be used?

The LuxaPrint material for each print job is selected at the software level when preparing the job in Netfabb, with the resin bottle using RFID technology and is identified by the printer.

What is the nesting and slicing software used?

The nesting and slicing software used is Netfabb by Autodesk.

Can custom supports be added?

Yes, custom supports can be added to a device in Netfabb.

How often should the 3Demax be calibrated?

The calibration of the 3Demax is a quick and easy process that needs to be performed weekly.

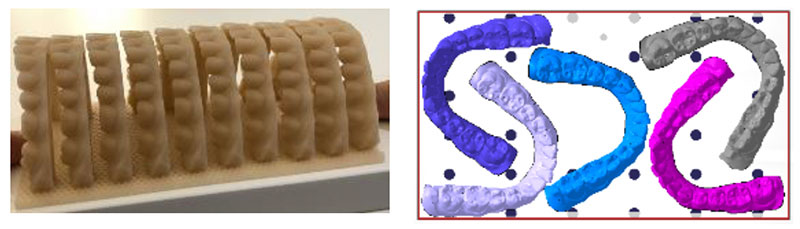

How many models can you print?

You can print 10 models vertically. You can print 5 models horizontally.

How long does it take to print models?

10 models vertically can be printed in approximately 90 minutes.

5 models horizontally can be printed in approximately 27 minutes.

Is the DMG 3D Digital Printing Solution a closed or open system?

The DMG 3D Digital Printing Solution is an open system. Third party resins can be added to the solution; however, they are not considered validated.

Is there installation/setup available?

There is an option of a virtual or in-person installation (travel costs will apply). The installation process is not difficult, and it takes half a day to complete. In preparation for the installation, a checklist will be sent to the customer. A Technical Specialist is available for support.

Is there training available?

Yes, there is training available. There is an option of a virtual or in-person training (travel costs will apply). Training takes about 1-1.5 days to complete depending on number of people and 3D printing experience. Customer will be contacted to schedule training once.

Can a printed sample be requested?

Yes, a sample can be requested at DMG-Connect (https://dmg-connect.com/digital-sample-request/). Click here to request a sample or submit an STL file for printing.

Is there a warranty?

Yes, there is a warranty that is activated with the submission of the Handover Report at the time of installation.

What is the length of the warranty?

The warranty is valid for 12 months.

What does the warranty cover?

The warranty covers failure of parts, and the related labor and shipping costs. It does not cover wearing of parts and disposables.

What safety precautions will I need to take?

Gloves should always be used for protection against touching raw resin material. UV Glasses should be worn for protection of the eyes from the UV light and paper towels/wipes should be used for cleaning of machines, trays, area etc.

3Dewash

What is the purpose of the 3Dewash?

The 3Dewash cleans the printed dental devices with 99% isopropyl alcohol. The pre-programmed wash cycles are tailored to indication and material and wash the remainder of raw resin from devices.

Can a different solution other than alcohol be used with the 3Dewash?

Only 99% isopropyl alcohol can be used with the 3Dewash.

Can the 3Dewash connect over Wi-Fi?

Yes, the 3Dewash can connect over Wi-Fi.

3Decure

What is the purpose of the 3Decure?

The 3Decure provides the final step of the process, curing. The pre-programmed curing cycles ensure accurate curing and are tailored to indication and material. The 360 UV hardens the printed device.

Can the 3Decure connect over Wi-Fi?

Yes, the 3Decure can connect over Wi-Fi.

LuxaPrint Resins

What packaging sizes are available?

Currently there are 3 available sizes: 200g, 500g, 1kg

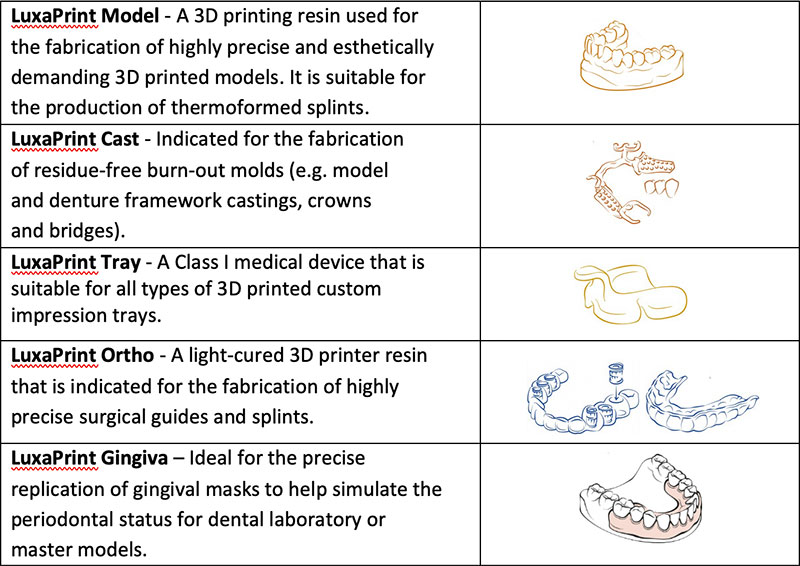

What are the available LuxaPrint resins?

The following are the available DMG resins:

Can I store unused material?

Unused material can be stored by placing the resin reservoir lid on the resin reservoir or can be filtered and poured back into the bottle.

How long can you leave LuxaPrint resin in the resin reservoir?

There is no limitation on how long a LuxaPrint resin can be kept in a resin reservoir. The resins should be stored in a dark and dry place. It is recommended to filter the material and to mix the material before re-use.

Is the ortho material a clear material?

The ortho material is a transparent color.

Can the ortho material be autoclaved?

Yes, it is autoclavable.

If you autoclave the ortho material will it change color?

No, the material will stay transparent during the whole process.

Can the LuxaPrint resins be recycled?

Yes, resins can be filtered and poured back into the resin bottle for storage.

How are the LuxaPrint resins stored?

Resins can be stored in the resin reservoir covered with the resin reservoir cover. A storage system is available that holds 5 resin reservoirs. Alternatively, resin can be filtered and poured back into the resin bottle for storage.

What is the shelf life of the LuxaPrint resins?

The shelf life of the resins is two years except for LuxaPrint Gingiva which has a shelf life of one year.

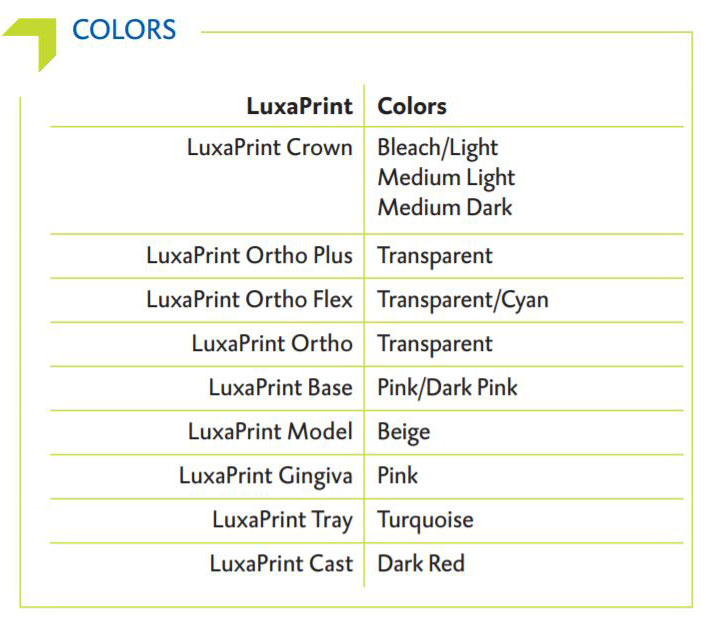

What are the colors/shades of each printed device type?

These are the available shades. LuxaPrint Model will also have a grey color/shade.

Can a flash box be used for curing LuxaPrint resins?

Yes, a flash box can be used to cure LuxaPrint resins. The IFU has instructions.

Can resins be mixed?

We do not recommend mixing resins.

Can I use third-party resins?

Yes, third party resins can be used with the 3Demax if the resins are indicated for use with a DLP 385 wavelength printer. The third-party resin parameters need to be added to Netfabb and tested.

DentaMile Lab5 & Lab 5 Pro

What is the size of the build platform?

The DentaMile Lab 5 build platform size is 9.09 x 5.11 x 11.8 inches (LxWxH) or 231 x 130 x 300 mm

The DentaMile Lab 5 Pro is 9.09 x 5.11 x 3.93 inches (LxWxH) with ASM or 231 x 130 x 100 mm with ASM

What is the size of the DentaMile Lab5 Pro?

The DentaMile Lab 5 Pro printer size is 23.6 x 22.44 x 65.35 inches (LxWxH) or 600 x 570 x 1660 mm

What comes with the DentaMile Lab 5 Pro?

The following is what is included with the DentaMile Lab5 Pro 3D printer:

- Power cord

- Resin reservoir

- Build platform

- Calibration glass

- Calibration plate

- Light Sensor

- Automatic Separation Module (ASM)* (ASM blade, blade cover, catch basket)

- Resin refill tube*

- Resin bottle and resin canister holder *

*Lab5 Pro only

What are the features of the Lab5 Pro?

- Large build area for multiple device production

- High-precision 4K light source

- RFID technology for automated material identification

- Fast print speeds via Force Feedback technology

- Heating of print chamber up to 95° F / 35° C

- Compatible with standard dental CAD software (STL files)

- Large status LED bar

- Automatic hands-free hood opening

- Automatic separation of the finished printed devices (ASM)

- Automatic resin reservoir refill

- Intelligent connectivity with post-processing units

- Software-supported, validated workflow for reproducible dental devices

What is the resolution of the DentaMile Lab5 Pro?

The resolution on the DentaMile Lab5 Pro is 4k resolution.

What is the native pixel size?

The native pixel size is +/- 30 um

How many models can you print per build?

You can print approximately 7 full arch models, or 9 aligner models.

Is there any heating available?

The Dentamile Lab 5 Pro has a heated printing chamber.

How will the Dentamile Lab5 Pro be shipped?

The Dentamile Lab5 Pro will be shipped in a large wooden crate.

Does the DentaMile Lab5 Pro use 3rd party resins?

Yes, the DentaMile Lab5 Pro has an open library of resins.

What is ASM?

ASM stands for Automatic Separation Module. When printing is completed, parts are automatically separated from the build platform via a blade and deposited in a collection basket.

Is the ASM removable?

Yes, the ASM is removable.

How many times can you use the ASM blade before it needs to be replaced?

The ASM blade will need to be replaced approximately around 500 uses.

How many times can you print on a resin reservoir before replacing it?

You will be able to use a resin reservoir approximately 250 print jobs.

How does the Automatic Resin Refill work?

The DentaMile Lab5 Pro has a fluid level sensor that will detect when the reservoir needs more resin and will automatically fill to a certain level.

Can the DentaMile Lab5 Pro connect to the internet?

Yes, the DentaMile Lab5 Pro uses Ethernet or WiFi to connect to the internet.

How does the Lab5 Pro print automatically?

First, configure a job queue. After a job is finished, The ASM will remove the print job off the build plate and collect them in the parts basket. Once the job is removed from the build plate, the next job in the queue will start up automatically.

Is slicing software included with the DentaMile Lab5 Pro?

Yes, Netfabb is the slicing software that is included with the DentaMile Lab5 Pro.

DentaMile Desk MC-5

What type of file can the DentaMile Desk MC-5 print?

The DentaMile Desk MC-5 can print any STL, OBJ and PLY files.

How many models can you print with the DentaMile Desk MC-5 printer?

The build plate of the DentaMile Desk MC-5 printer can easily fit two arches lying flat and up to 6 standing up.

What is the wavelength of the DentaMile Desk MC-5 printer?

The wavelength of the DentaMile Desk MC-5 printer is 385 nm.

Is nesting and slicing included with the DentaMile Desk?

Yes, the DentaMile Desk MC-5 printer uses a software called DentaMile CAM MC that is included with the system. The printer can also print jobs directly from DentaMile connect, a cloud-based software that offers automatic nesting and slicing.

How long does it take to print a model?

The print time for printing a model can be between 30-90mins depending on orientation and materials.

How does the speed of the DentaMile Desk MC-5 printers compare to other printers?

The DentaMile Desk MC-5 is comparable if not faster than many similar printers in the market.

Is the DentaMile Desk MC system a closed or open resin library?

Currently the DMG LuxaPrint resins are validated on the printer which offer a wide range of indications.

How long does the resin reservoir last?

The resin reservoir can last up to 100 prints. Depending on usage, this is usually about half a year of printing.

Do I need to buy additional resin reservoirs?

It is recommended to have additional resin reservoirs for efficiency when printing with other resins; it will reduce the time between replacing resins.

Is the DentaMile Desk MC-5 printer easy to clean?

Yes, the printer is self-contained, and easy to clean. The parts of the printer that can be cleaned such as the build platform can be done with isopropyl alcohol to wipe any resin that might have dripped.

Does the DentaMile Desk MC-5 printer need to be calibrated? How often?

Yes. To ensure the highest quality for your prints, the MC-5 has a weekly light intensity check.

Is there a warranty?

Yes, there is a warranty that is activated with the submission of the Handover Report at the time of installation.

What does the warranty cover?

The warranty covers failure of parts, and the related labor and shipping costs. It does not cover wearing of parts and disposables.

What is the length of the warranty?

The warranty is valid for 12 months.

Is customer support available?

Yes, our team of digital specialists are available assist with any support questions.

Is training offered?

Yes, training is available. There is an option of live virtual or in-person (travel costs will apply). Training takes up to 8 hrs to complete depending on the number of people and 3D printing experience. Customer will be contacted to schedule training once the sale is completed.

What accessories are available with the DentaMile Desk MC system?

The DentaMile Desk MC-5 is complete with standard accessories ensuring successful prints from day 1!

How do I post-process after printing with the DentaMile Desk MC-5 printer?

The DentaMile Desk MC-5 printer has two compatible and validated post-processing units, the DentaMile Wash MC for cleaning your prints, and the DentaMile Cure MC for curing your prints.

What is the accuracy of the DentaMile Desk MC-5 printer?

The DentaMile Desk MC-5 has a resolution of +/- 34 microns in the x and y direction and can support layer thickness as low as 50 microns.

Is there installation/setup available?

There is an option for live virtual or in-person installation (travel costs will apply). The installation process is not difficult, and it takes a couple of hours to complete. In preparation for the installation, a checklist will be sent to the customer. A Technical Specialist is available for support.

DentaMile Wash MC

What is the purpose of the DentaMile Wash MC?

The DentaMile Wash MC cleans the printed dental devices with 99% isopropyl alcohol. The pre-programmed wash cycles are tailored to indication and material and wash the remainder of raw resin from devices.

How do I change out the alcohol of the unit?

The basin within the DentaMile Wash MC is removable allowing for easy swapping and disposal of alcohol.

How often should I replace the alcohol in the DentaMile Wash MC unit?

It is recommended to change the isopropyl alcohol once every 15-20 wash cycles.

How much alcohol is used in the DentaMile Wash MC?

The DentaMile Wash MC unit can hold 0.4 to 1 liter of alcohol.

Do I need to buy additional wash basins?

It is recommended to have additional wash basins so that bio-compatible resins are not cross-contaminated with non bio-compatible resins.

DentaMile Cure MC

What is the purpose of the DentaMile Cure MC?

The DentaMile Cure MC provides the final step of the process, curing. The pre-programmed curing cycles ensure accurate curing and are tailored to indication and material. The unit is equipped with Omni 360° technology for uniform curing (all 6 sides) of the printed device.

Does the DentaMile Cure MC use a vacuum or Nitrogen gas?

No, the DentaMile Cure MC does not use gas; it has no gas input.

What wavelengths can the DentaMile Cure MC effectively cure?

The DentaMile Cure MC can cure 365, 385 and 405 nm wavelength resins.

Can the DentaMile Cure MC connect over Wi-Fi?

Yes, the DentaMile Cure MC can connect over Wi-Fi.